Tuesday, April 22, 2014

POST 1298; APRIL 22, 2014; HOOKER, OKLAHOMA

Crossing OKLAHOMA Panhandle, towns are only 10 miles apart. At 4 mph, walking 10 miles takes only 2.5 hours. Still recovering from high altitude breathing problem, so it is good to have easy walking for a while. Wind is still a problem. Weather forecasts possible thunder storms for later this week. I do not want to be caught out walking in thunder storms, so am pushing to get walking done in early morning hours

Walking early this morning from GULMON, Texas toward the town of HOOKER, some18 miles distant.

MURAL being added to a building in GUYMON.

US 54 is still 4-lane. Makes for pleasant safe walking, except on town outskirts where a curb is used instead of a berm.

Came across this Circular Irrigation System.

This system rotates from a fixed position in a circle encompassing large area of irrigated land.

The above is but one section of 120 feet. Typical Plains installations incorporate up to 10 sections, producing a circumference of 1,200 feet. In other parts of the USA, units are MUCH longer.

The entire unit rotates around the fixed point shown above.

Irrigation wate enters the 10 inch dianeter feet pipe at 600 gallons per minute...

...and is fed throgh a series of drop pipes to get the water as close to the ground as possible. The wind being so continuously strong, release of water any higher will result in a good percentage of applied water being blown away before gravity pulls it to the ground.

In less violent climes, pressure fed sprinklers are often used to spray irrigation water many feet to either side of the central unit.

Each drop water pipe has a sprinkler head attached to regulate water flow. Water is metered out of the nozzle at 6 psi (6 pounds per square inch.) with provision to adjust itself in event the unit is working on a hill where water could gravity flow to one end or another; i.e. assures proper water flow to each sprinkler head.

The unit's central feed pipe is the backbone strength. Angle Iron segments are engineered to support the entire structure.

Each unit has two "towers", one at each end. One end has a 240v DC single speed electric motor with double extended output shafts...each shaft coupled to deep tread inflatable tire assemblies to drive the unit forward in it's circle.

The driven end of a section is "Hitched" (similar to a vehicle Cup and Ball Trailer Hitch) to the "idler" (non driven) end of the next section in line. A steel alignment bar, attached to one of the units, is connected to a time phased limit switch which turns the electric motor on and off, keeping all units in alignment.The most distant section - farthest from the pivot point - is the "guide". All other sections align themselves to Tail End Charlie.

Drive Motor and Gear Box cutaway.

Drive Wheel Gear Box Cutaway below. Worm Gear assembly detail above pic.

Please say HELLO to JERROD, Chief Service Technician of GIGOT AGRICULTURE PRODUCTS, with whom I spent considerable pleasant time learning about sprinklers.

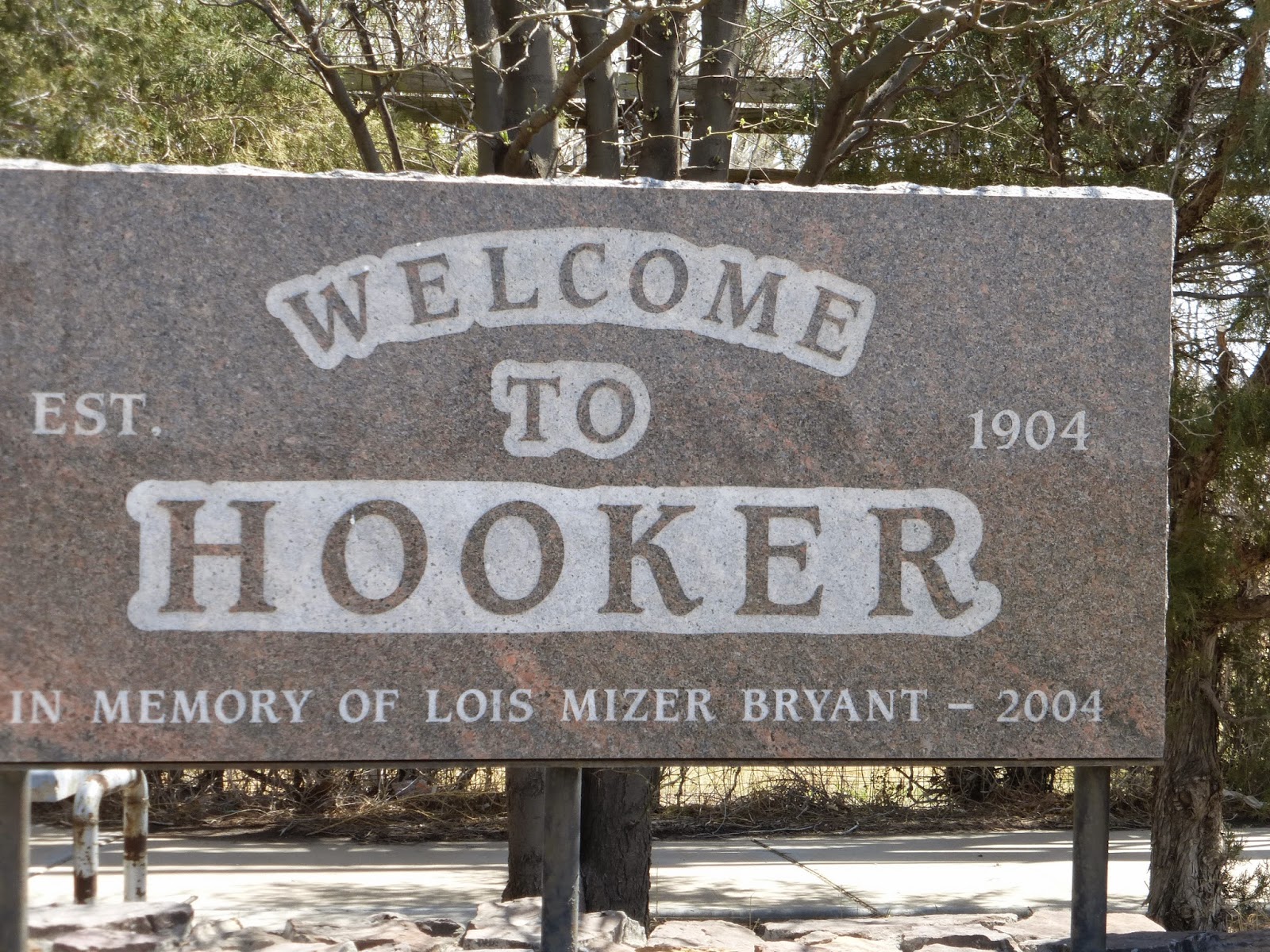

For the rest of the day and overnight, we drive the 18 miles to the town of HOOKER, Oklahoma.

...where our walk BACK toward GUYMON picks up the driven miles.

HOOKER POINT Park in the format of a museum.

Buckboard Waggon.

Shoe Brake detail. A hand brake lever leads to the right hand of the driver.

All metal components appear to be hand forged.

Vintage Farm Tractor

Hand guided dirt scraper. In the late 1930s, we used such a unit, pulled by the pickup truck. The Scraper Blade Operator guides direction and depth using two handles as he walks along behind the towed scraper.

My Grandfather used a team of horses to pull the same contrivance as he built a road to his homestead near Great Dry Falls in the COULEEs below Grand Coulee Dam. At the time, POP was running Sheep on horseback. I often helped him tan leather and fashion HACKAMOREs in his SEATTLE garage during the 1940s. The SEATTLE TIMES called POP THE LAST TRUE COWBOY in its color Sunday Addition.

Wringer Washing Machine (less the wringer head), in which I got my hand caught feeding wet washed clothes into the rubber spring loaded rollers. Mother used a short cedar paddle to feed cloths into the rollers.

The galvanized pan hanging on the wall, we used to make home-brew Root Beer...and served as my bath tub. We had no running water. Water was heated on the wood burning kitchen stove.

Pics of what there is...is what we get. Sometimes, hundreds of miles go by unchanged.

4-lane highway is still with us. Some concern as to how many more years the mid west can hold out with decreasing water tables. Takes lots of grain to fill those elevator silos.

Most popular "FARMALL" tractor. Please flip back to the Museum pic...note not much basic design change between the two machines.

Tanker hauling "Liquid Fertilizer".

18 Wheeler with a serious looking ROO GUARD.

Old West Steam Trains called the reinforced grating up front a "Cattle Catcher".

Australians call such a reinforced guard a ROO GUARD (to protect the vehicle from crashes with Kangaroos.

Not certain what they are called nowadays, but I know SPIA-2 two times was flattened to the windshield when I drove her at night at 75 mph broadside into a deer crossing the freeway - once in MONTANA and once in UTAH -.

Could have used a ROO Guard.

* * * * * * * * * *

Tomorrow, should enter KANSAS...still on US 54.

Subscribe to:

Post Comments (Atom)

1 comment:

U R Crossing lot of states Must be interesting!! B & E

Post a Comment